So, I hope that through experimentation, you're able to get a better feel for columns and maybe discover what factors affect how a column will behave. So, how do columns fail? It turns out there are two different ways a column can fail. They can buckle. Buckling just means it displaces laterally or horizontally. In this case, the middle is displacing. Long, slender columns like this one will tend to buckle. You could also have a compression failure. A compression failure is when the material itself crushes or yields. These shorter, wider columns will fail in compression. So, how do we predict failure? I'm going to start with compression failure and I'm going to use a small blue foam beam. When I push on it hard enough, I can shorten the column. That downward force is the compressive force. I often model that with a downward arrow. If I push hard enough, I can cause failure. But I can't push hard enough on this one to cause failure. I did bring a piece of chalk, also a fairly short, wide column with a circular cross-section. I'm not strong enough to push it to cause failure, but I think if I use my hammer, I can apply a large enough load to cause it to fail. That will mean that my applied force and stress is higher than the allowable. When I apply a compressive force to a column, it causes a stress in the column. The definition of stress is a force per unit area. But what does that mean? If we use this blue foam column as an example, when I push on the top, that's applying a compressive force. I usually denote that with a capital P and a downward arrow. That force gets distributed throughout the column and...

Award-winning PDF software

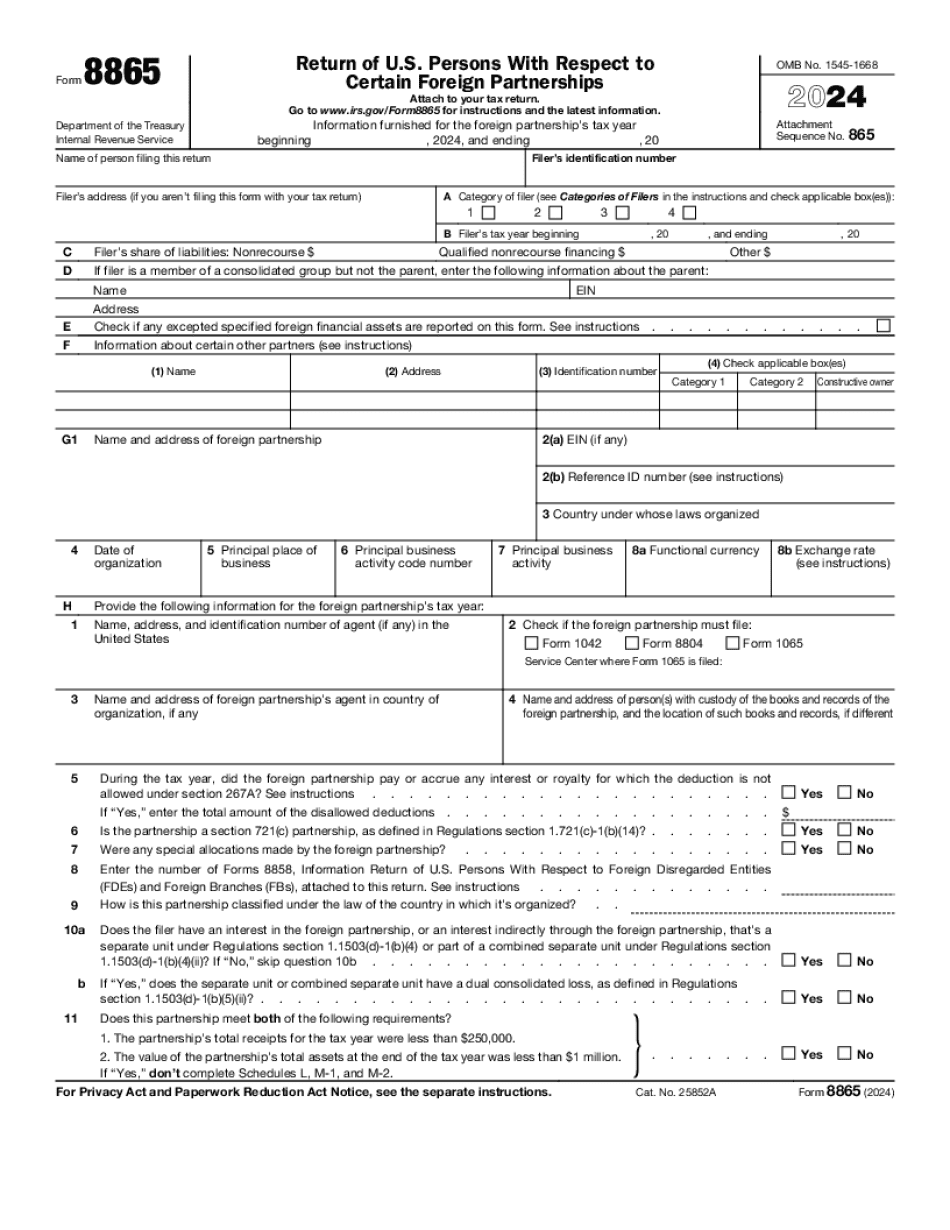

Video instructions and help with filling out and completing Can Form 8865 Columns