What's going on guys? I'm John Maliki and today we're building a reclaimed wood industrial filing cabinet. Here I am sawing down some old house timber to make the panels for the cabinet. I'm going to cut these down into whatever dimensions I need in my specs, from 1/2 inch to 3/4 to one inch, for the top, sides, and all the drawers. I do this first and glue those all up, and then I go ahead and assemble it after. Here I am gluing up a panel. I'm using daps rapid fuse, this is a cool product, it dries in 30 minutes. That way I won't have to keep things in clamps overnight, and it doesn't take as long to do an entire project. I'll glue up two panels here in these clamps and let them sit for about a half hour while I'm working on some other stuff, and by the time I'm done with that, these are ready to roll. Here I am ripping down the panels - with this pretty standard simple process. I go ahead and do everything a little heavy and wider when I'm doing a glue up, that way I can really dial in and adjust what I need perfectly after everything has dried. So after I cut down all the panels to width and length, I go ahead and cut down the face frame rails and stiles and use pocket holes to put those together. Blow up here is pretty simple, just putting the final rail in on the face frames. I go ahead and screw those in and get ready to assemble the carcasses for the cabinets. I like to pre-drill everything before I go ahead and assemble projects like this, it just makes my life easier. I'm using the Festool...

Award-winning PDF software

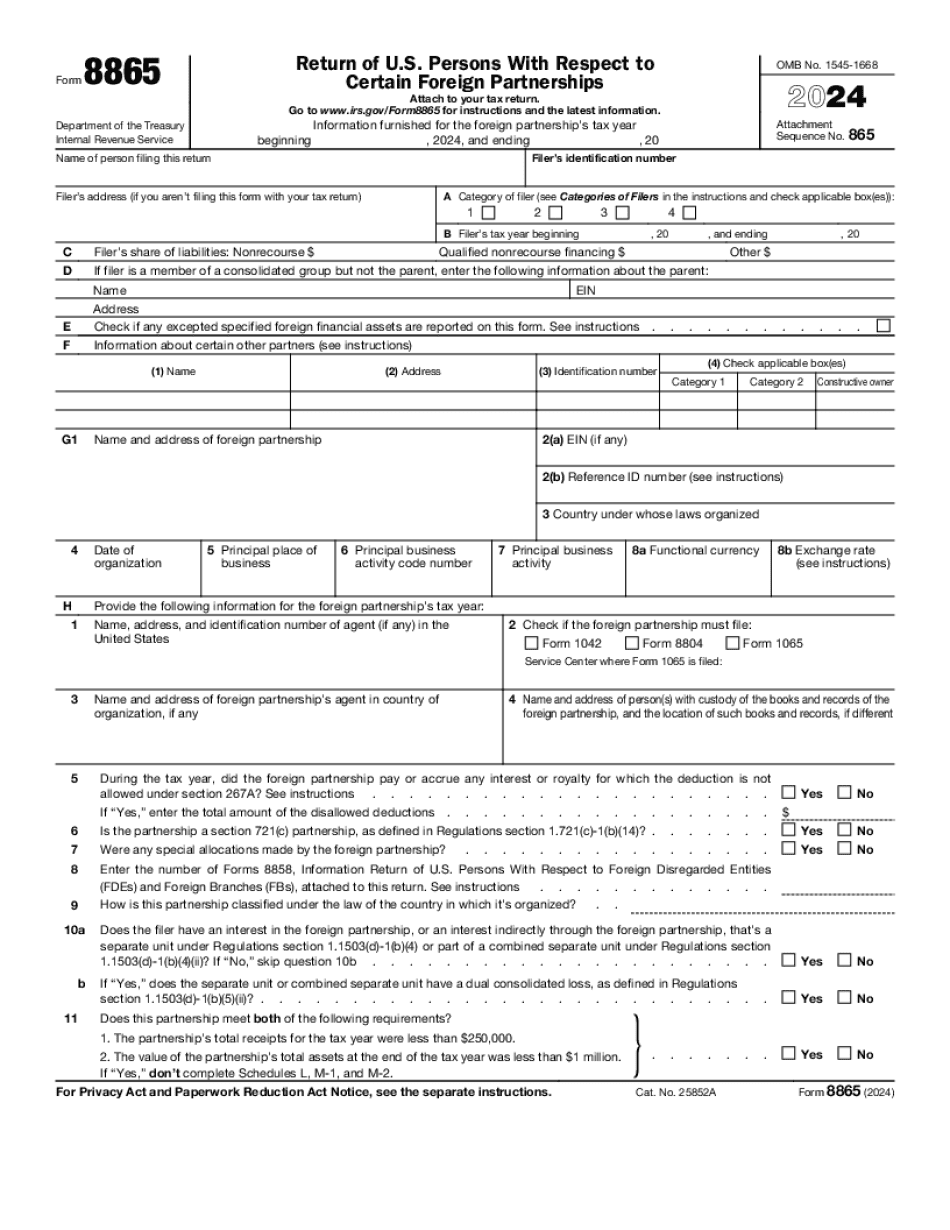

Video instructions and help with filling out and completing What Form 8865 Industries