Hey Jody here, this week's video is about a two-inch schedule 80 pipe welding test using a 60 10 route and 70 18 fill and cap. Today, Andrew Carden will be demonstrating the welding on pipe coupons provided by Triangle Engineering. We are filming at the Lincoln training and distribution center near Atlanta, Georgia. I'm going to try to minimize talking in this video because one of the benefits of watching a 60 10 route video is hearing the sound. I'll set up the pipe a little bit loose so that when I tack it, it will pull itself tight. Some procedures for this test limit the length of weld tacks to around 3/8 or 1/2 inch, so it's important to read the WPS (Welding Procedure Specification) to avoid any issues. Feathering the tacks is also necessary - sometimes a grinder is not allowed and a half-round file must be used. Feathering the ends of the tacks ensures a good tie-in both from and to the tacks. After tacking it up, do a little inspection with a light to ensure proper penetration. Grind out any areas that need it and redo any inadequate tacks before the inspector checks it. Watch as Andrew pushes the keyhole into where he feathered the tack, and then fills to avoid any fisheyes. This process is repeated on the other side as well. Keep the keyhole going and push it well into the tack to close it up. You may notice an arc struck inside the bevel - if you're going to have an arc strike, it's best to have them all inside and not outside on the pipe. The arc strike can be filed down or removed, but since this is a 60 10 welding process, it won't affect anything. You want to weld...

Award-winning PDF software

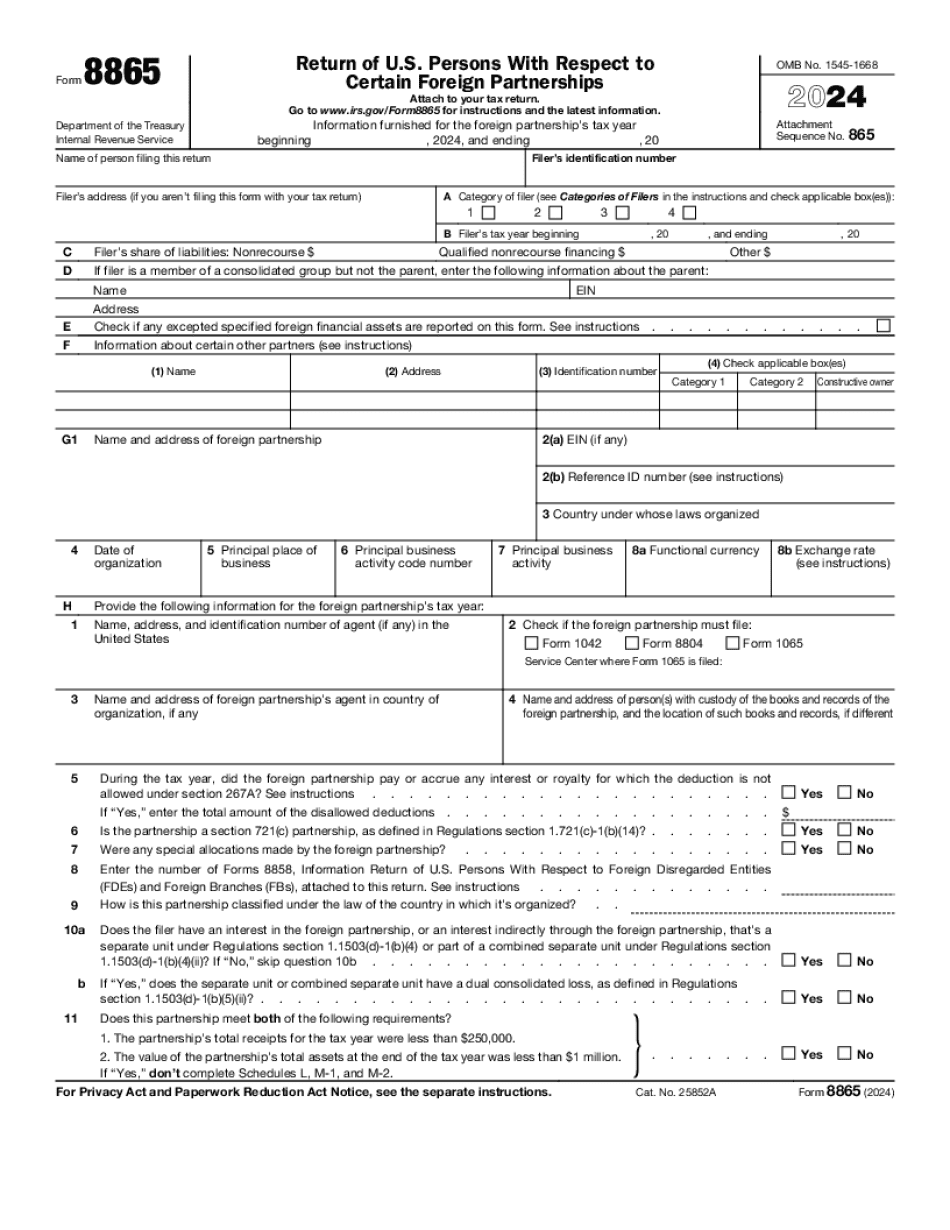

Video instructions and help with filling out and completing What Form 8865 Schedules