Hey everyone, what's going on? I'm John Maliki and today we're building a reclaimed industrial vanity. This will be a two-part series. In the first part, here you're going to watch me weld up the frame, and in the second part, I'll be putting together the cabinets. So, here's what I'm doing. I'm taking my Evolution Rageous - chop saw and cutting down all my parts for the metal casket. The saw here is a pretty awesome tool and it leaves some nice clean cuts. I'm not beveling all the edges to give me some good penetration with my welds. For this project, I'll be using my Lincoln 210 MP MIG welder. I love that machine. It's really easy to dial in and it fires up super quick, putting down beads very fast. I don't really have to go through much setup time. Here, you can see I am tacking up the frame, making sure everything's square. I like to use magnets to keep things square, and then I'll just make sure I consistently tape out for the spacing. Here, I cut a spacer since I have to do four of these external frames. It's just easier to give yourself something to reference off of the base. I went ahead and measured from the bottom up for that because I knew my spacing there, and I go ahead and tack the whole thing together off film. I do four of these, and they are the external sides to the vanity itself. Here, I'm putting the finish welds on to the external carcass pieces. I'm just making sure that everything is aligned square where I want it. I leaned it up so I can get the bottom. I'm not putting any welds on to the top or the insides where I'll have any of the...

Award-winning PDF software

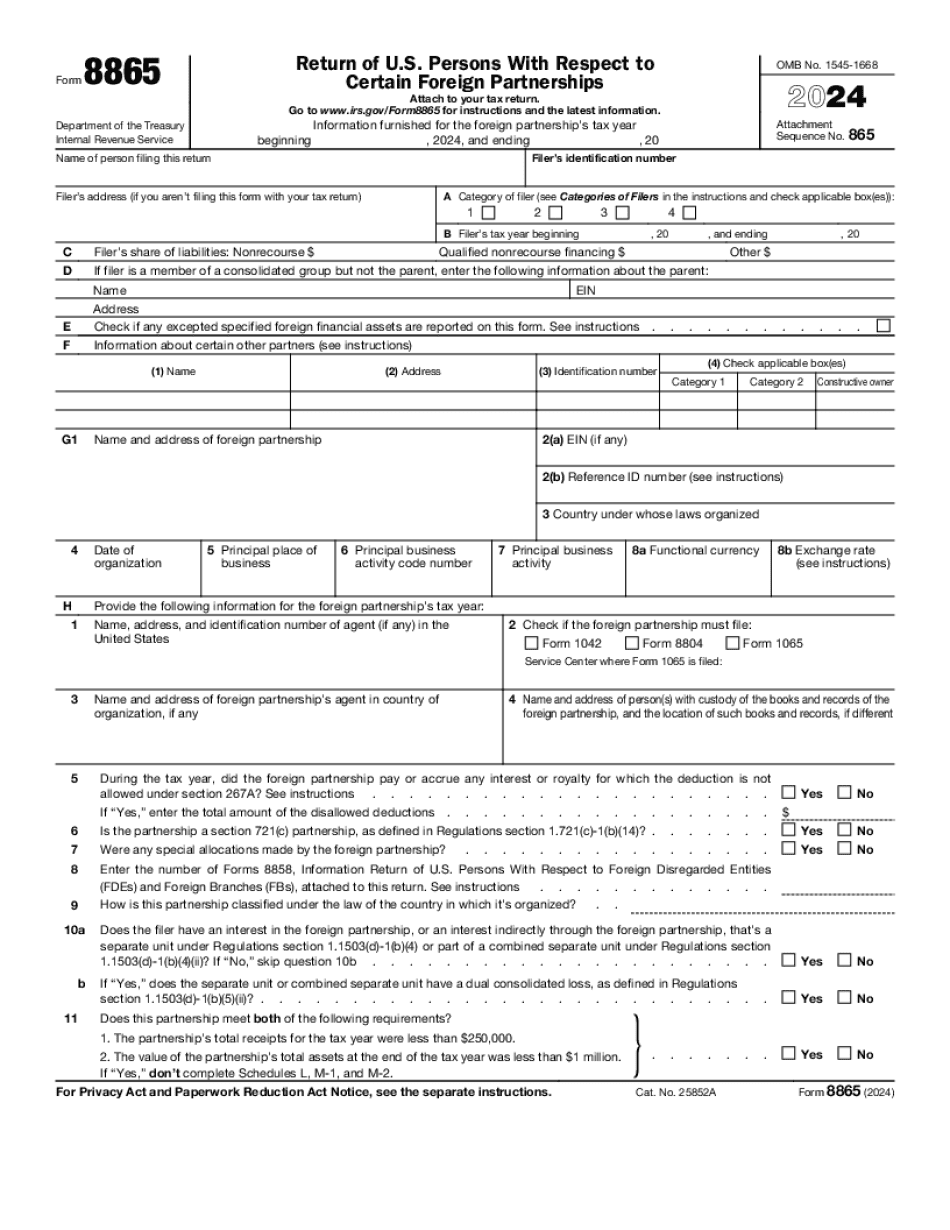

Video instructions and help with filling out and completing Which Form 8865 Industries